CCK Automations, Inc. is a premier manufacturer of IPC-A-610 certified printed circuit board assemblies (PCBAs). Equipped with over 20 years of electronic product manufacturing experience, more than 100 highly skilled employees, and a broad selection of high-tech production machines, we have the knowledge, skills, and tools needed to produce PCB assemblies for nearly any customer, industry, or specialized need.

CCK Automations, Inc. is a premier manufacturer of IPC-A-610 certified printed circuit board assemblies (PCBAs). Equipped with over 20 years of electronic product manufacturing experience, more than 100 highly skilled employees, and a broad selection of high-tech production machines, we have the knowledge, skills, and tools needed to produce PCB assemblies for nearly any customer, industry, or specialized need.

What Is a PCB Assembly?

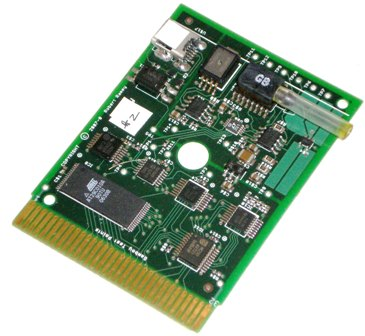

The terms “PCB” and PCBA” are often incorrectly used interchangeably. PCBs—i.e., printed circuit boards—refer to the bare rigid, rigid-flex, or flexible component on which electrical or electronic components are mounted and connected by engraved conductive pathways. They have the circuit pattern printed on them, but the electrical and electronic components are not yet attached. The process of attaching and soldering the necessary components to the printed circuit board is known as PCB assembly. The fully assembled circuit board is then referred to as a printed circuit board assembly.

How Are PCB Assemblies Created?

PCB manufacturers rely on three methods to turn PCBs into PCB assemblies:

- Plated Through-Hole (PTH) Assembly: PTH assembly is used for electronic components that contain leads. These leads are inserted into plated holes in the PCB, then soldered into place.

- Surface Mount Assembly: Surface-mount components come with metal tabs that are soldered directly onto the surface of the PCB. The primary benefit is a quicker installation process, but surface mounting also allows for higher circuit densities. With PTH components, each component takes up space on both sides of the PCB, whereas a surface-mount component only occupies a region on one side.

- Electromechanical Assembly: Electromechanical assembly—also referred to as box-build assembly—involves all of the assembly work involved in manufacturing electromechanical assemblies other than making the PCB component. Manufacturers use various elements, such as wire harnesses, cable assemblies, and molded plastics, to attach the electronic components to the PCB.

All of these PCB assembly processes require significant attention to detail as any lack of accuracy or precision can affect the performance of the electronic device in which the finished PCBA is installed.

What Materials Make Up a PCB Assembly?

PCBs consist of several layers—the substrate, the conductive pathways, the solder mask, and the silkscreen—each of which is made from different materials.

PCBs consist of several layers—the substrate, the conductive pathways, the solder mask, and the silkscreen—each of which is made from different materials.

- Substrate: The substrate is the base layer of the PCB. It can be made from rigid, rigid-flex, or flexible materials, depending on the intended application.

- Conductive Pathways: The conductive pathways are made by adding a thin layer of conductive foil to the functional side(s) of the substrate. The material is added to one side in single-sided PCBs and both sides in double-sided PCBs.

- Solder Mask: The solder mask is applied on top of the copper layer. It gives PCBs their characteristic green color, insulates the copper layer from accidental contact with other conductive materials, and prevents solder from adhering to the wrong places on the PCB.

- Silkscreen: The silkscreen is the final layer added to a PCB. It adds alphanumeric and symbolic labels—typically in white—that indicate the function of each component added to the board. These labels help clarify the intended design for technicians during initial assembly and repair work.

Types of PCB Assemblies

Printed circuit board assemblies are available in several designs and configurations to suit different applications. These variations can be categorized into a number of broad classifications depending on the critical design element.

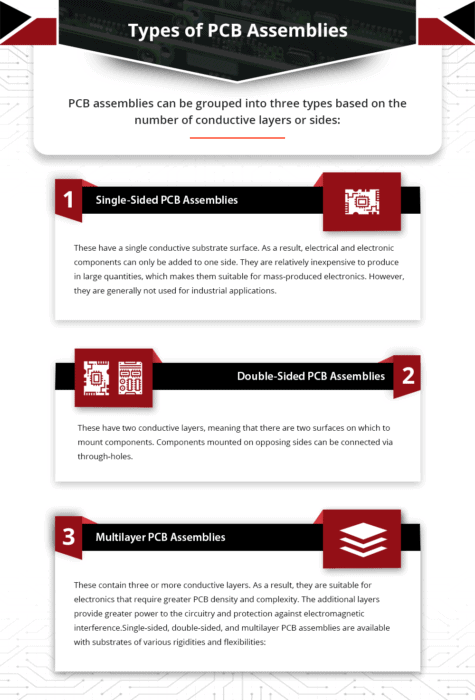

PCB assemblies can be grouped into three types based on the number of conductive layers or sides:

- Single-Sided PCB Assemblies: As the name suggests, single-sided PCB assemblies have a single conductive substrate surface. As a result, electrical and electronic components can only be added to one side. They are relatively inexpensive to produce in large quantities, which makes them suitable for mass-produced electronics. However, they are generally not used for industrial applications.

- Double-Sided PCB Assemblies: Double-sided PCB assemblies have two conductive layers, meaning that there are two surfaces on which to mount components. Components mounted on opposing sides can be connected vita through-holes.

- Multilayer PCB Assemblies: Multilayer PCB assemblies contain three or more conductive layers. As a result, they are suitable for electronics that require greater PCB density and complexity. The additional layers provide greater power to the circuitry and protection against electromagnetic interference.

Single-sided, double-sided, and multilayer PCB assemblies are available with substrates of various rigidities and flexibilities:

- Rigid PCB Assemblies: When most customers think about PCBs, they imagine rigid ones—thin but inflexible boards with printed circuitry. This rigidity comes from the solid and rigid substrate employed (e.g., fiberglass). Typical applications for rigid PCB assemblies include computer towers, laptops, consumer electronics, and industrial control mechanisms.

- Flexible PCB Assemblies: Flexible PCB assemblies utilize flexible substrates that allow them to bend to fit into small and tight spaces without damaging the circuitry. While they are more expensive than rigid PCB assemblies, they offer a number of advantages, such as accommodation of smaller space and weight limits. This quality makes them well-suited for use in aerospace, military, and other similar applications.

- Rigid-Flex PCB Assemblies: Rigid-flex PCB assemblies combine segments of rigid board and segments of flexible substrate. They help reduce and/or eliminate the need for connectors and improve labor, yield, transmission, and reliability problems. These PCBAs are highly versatile, finding application in a variety of industries, including aerospace, consumer goods, medical, and military. The main disadvantage is their comparatively high price point.

Both flex and rigid-flex PCB assemblies can be designed for either static-flex or dynamic-flex applications. Static-flex PCB assemblies are intended to bend only for installation, typically as a means of fitting them into a small or tight space. Dynamic-flex PCB assemblies are used in products that experience repeated bending.

Quality Printed Circuit Board Assemblies (PCBAs) at CCK Automations

At CCK Automations, Inc., we design and manufacture IPC-A-610-certified printed circuit board assemblies for customer-specific, industry-specific, and specialized applications. Our manufacturing facility houses all of the tools we need to develop and deliver quality PCB assemblies, including three high-speed surface mount lines, prototype lines, auto insertion equipment, spade insertion equipment, vapor reflow technology, automated optical inspection machines, and X-ray machines. This equipment allows us to provide a broad selection of PCBA capabilities to meet the various PCBA needs of our customers, including:

- 3D Automated Optical Inspection

- BGA and Micro BGA

- Tin Lead Wave

- Lead-Free Wave

- Tin Lead Selective Solder

- Lead-Free Selective Solder

- Conformal Coating

- Dip Coating

- Selective Coating

- Potting

- Robotic Potting

- Staking

- Robotic Staking

- Robotic Gasketing

- Wire and Cable Assemblies

- Hand Assemblies

- Box-Build

- Complete Testing

- High-Volume Testing

- Labeling

- Customer-Specific Labeling

- Packaging

- Foam-in-Place Packaging

- Full ESD Control Measures

- Custom Packaging

- Customer-Specific Packaging

- Low-Medium-High Volume Assemblies

- 0201 and Up Package Types

- Surface Mount Line Placement to 70 Micron Accuracy

In addition to our PCB design, manufacturing, and assembly capabilities, we also offer a full range of in-house injection molding services. As a result, our customers experience the benefits of partnering with a PCBA supplier that completes all design and manufacturing processes under a single roof, such as greater control over product quality, lower freight costs, and faster turnaround time.

For printed circuit board assemblies tailored to your needs, you can count on the expert at CCK Automations. Contact us today to learn more about our PCBA capabilities or request a quote.